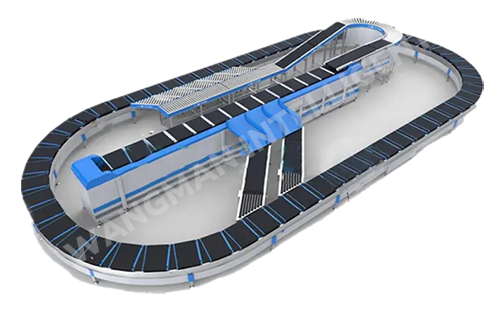

Cross Belt Sorter

In addition to the high speed and sorting efficiency, it can also handle items of various specifications and sizes, including fragile items and items with high friction coefficient and do sorting work on both sides at the same time.The one-side sorting efficiency generally can reache 8000-12000 pieces per hour. It has many advantages such as high efficiency, flexibility and high site utilization rate. It is a kind of sorting solution to achieve maximum economic benefits and high reliability.

System composition:

Semi-automatic packages table : with barcode scanning system, weighing system.

- Cross Belt Sorter: including trolleys, racks, maintenance platforms, step lads can be customized.

- Grid module: including chute, bag support bracket, grid button, full package of photoelectric, etc. The number of grids can be customized.

- Parcel Detection Module: Contains empty disc detection and parcel correction.

- Upper computer system: WCS system, realising the data interface with the customer's system.

- Monitoring system: operation management system, realising human-machine interaction, data statistics, equipment monitoring and other functions.

Sorting Tray:

- The loading trolley is driven by servo electric roller with low power consumption and stability.

- The electric roller has a built-in encoder, so the sorting action is accurate.

- The trolley is made of a wear-resistant belt with a diamond pattern, which provides a firm grip on the goods without slipping and low belt wear.

- The body is made of a large number of lightweight aluminium alloys, energy saving and high strength.

Infeed Conveyor:

Product Features:

1.Simplicity

Weighing and scanning all-in-one design, easy to operate.

2.Barcode Accurate

600W industrial all-in-one camera with strong barcode resolution.

3.Packet supply accuracy

Servo motion control, loop speed matching more accurate, reduce the probability of wrong score.

Advantages:

1) Low energy consumption linear motor, non-contact drive, high effciency and energy saving.

2) Sorting of items of various specifications and sizes. Achieving efficient sorting of fragile and high friction coefficient items.

3) Real-time dynamic tracking technology,systemmonitoring, diagnosis and security protection functions.

4) Modular design,easy maintenance,high stability.

5) High efficientcy vision plan, high accuracy data collection,reduces labor resources.

6) High output 8000-10000 parcels per hour Wide ranges of items sortable.

7) Easy maintenance, compact structure, open for adding more sorting ports/expandable.

Technical parameters:

| Item | Parameter |

|

System Driven |

Bilateral AC Linear Motor |

|

Tray pitch |

600/750/800/1200mm(2 trays and 1 belt) |

|

Tray length |

700-1100/1400mm |

|

Width of tray belt |

420-620mm |

|

running speed |

1.2-2.4m/s(optional) |

|

Sorting capacity(one side) |

more than 12000 units per hour |

|

ways to provide parcels |

Automatic/semi-automatic/manual direct input (optional) |

|

System model |

2-N Logical Sorting System with 1 Ring Circle(customizable) |

| Item | Parameter | |

|

Automatic/Semi-automatic loading of parcel machine |

Loading capacity |

2500-3000piece/h |

|

Loading of parcel speed |

1-2.3m/min |

|

|

Power |

Section 3/4 |

|

|

Walking track |

Straight track section length |

2800/3000mm |

|

Turning section central radius |

3440/4586mm etc. |

|

|

Track material |

3T cold plate |

|

|

Surface treatment |

spraying |

|

|

Code reader |

Specifications |

Selection by bar code |

|

Cooperative Brand |

Datalogic/Sick/Cognex/Victronic |

|

|

Construction roller track |

Roller pitch |

700/750mm |

|

Roller length |

1000mm |

|

|

Sorting tray |

Driving mode |

48V bidirectional DC roller |

|

Pitch distance |

600-1200mm |

|

|

Pallet length |

700-1100mm |

|

|

Skin bandwidth |

450-620mm |

|

|

Maximum size of single tray |

30kg |

|

|

Maximum size of sorting goods |

1000L*500W*500H |

|

|

Outfeed chute |

Pitch |

700/750mm(customizable) |

|

Chutelength |

2800/3000mm |

|

|

Inclination angle |

270 |

|

|

Texture of material |

3T cold plate |

|

|

Bag holder |

Bag support pitch |

700/750mm |

|

Bag support ring |

500*500*15mm |

|